Optimizing Multilayer Blown Film : Key Factors & Advanced Machinery |

2023-05-08 | ||||||||||||||||||||||||||||

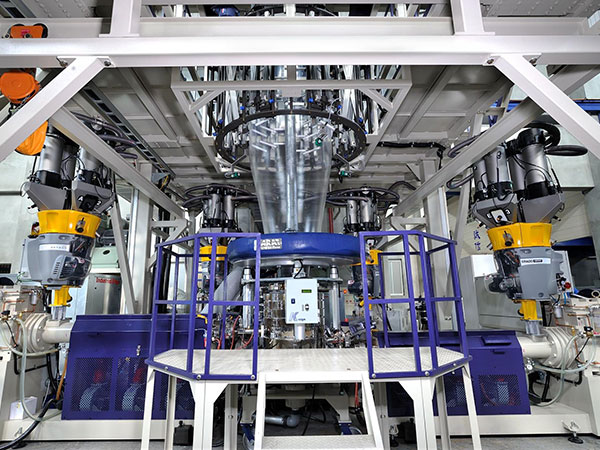

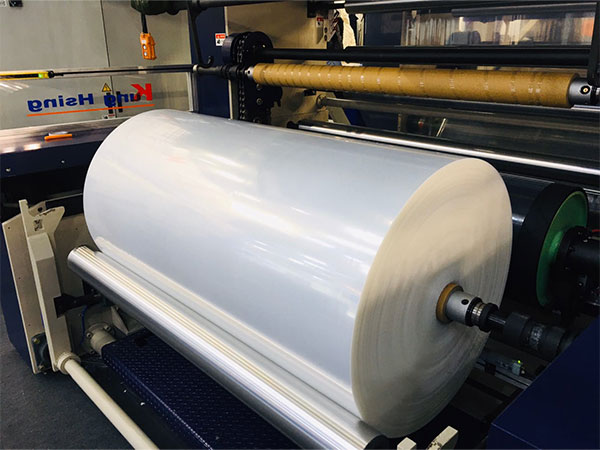

Blown film technology has undergone significant advancements in recent years, resulting in the development of innovative multilayer blown film designs. These designs offer superior performance in terms of barrier properties, strength, and diversity compared to traditional monolayer films. However, achieving optimal performance requires careful consideration of several key factors during the design process. In this article, we'll explore the key considerations for optimal performance of innovative multilayer blown film designs. 1. Blown Film Machine SelectionThe selection of a suitable blown film machine or line is crucial in achieving optimal performance of multilayer blown films. A blown film machine should be capable of producing films with uniform layer thickness, good interlayer adhesion, and high productivity. The machine should also be compatible with the materials used in the film to ensure efficient and reliable production. There are various types of blown film machines available in the market, including mono-layer machines and multi-layer co-extrusion machines. Multi-layer co-extrusion machines are commonly used for producing multilayer blown films as they offer higher flexibility in terms of layer arrangement for the specific function of each layer, higher flexibility in material formulation, the increase of film mechanical properties, and the contribution of sustainability.

Read Also : Advanced Agricultural Blown Film Machine : Producing High-Quality Wide Range Agricultural Films 2. Material SelectionMaterial selection is a critical factor in the design of multilayer blown films. Each layer of the film should be carefully selected based on its specific properties such as barrier, mechanical, and optical properties. The material selection should also consider the intended application of the film to ensure it meets the required performance specifications. Additionally, the compatibility of the different materials used in the layers should be taken into account to avoid delamination, unstable interface, and other defects. 3. Numbers of layersA multilayer blown film structure is crucial in achieving optimal performance, whether in an asymmetrical structure or symmetrical structure. 3 layers ABC and 5 layers ABCDE is the main stream in the blown film market nowadays, and the most common products are for lamination and printing film, consumer packaging, industrial packaging, and soft packaging industries. If you want to learn more about buying tips for 5 layer blown film co-extrusion lines, check out our comprehensive guide by clicking the following link : Guide to 5 Layer Blown Film Co-Extrusion Line. Additionally, 7 layers and up are used to produce high-barrier film and other special purposes. Common Applications of Multilayer Blown Film:

4. Layer ThicknessThe thickness of each layer in a multilayer blown film design is another critical factor that affects the film's performance. The thickness of each layer should be optimized to achieve the desired performance properties while minimizing material usage and production costs. The thickness of the barrier layers, in particular, should be carefully controlled to ensure optimal barrier properties.

5. Extrusion ProcessThe extrusion process used in the production of multilayer blown films plays a crucial role in the film's performance. The process parameters, such as melt temperature, pressure, similar characteristics of material, cooling efficiency, should be carefully controlled to ensure good interlayer adhesion and film quality. The use of advanced process control systems, such as gravimetric dosing systems to control thickness of each layer and stable output, and automatic gauge control, can further improve film quality and consistency. The mechanical design of the blown film machine should also be taken into consideration for achieving optimal performance. A screw design focuses on good material mixing, proper melting, consistent and homogeneous output. For the multilayer co-extrusion die, it has to take care of the pressure inside the die, proper shear stress, low resisting time, and appropriate layer distribution for each layer. 6. Testing and Quality ControlTesting and quality control are crucial in ensuring the optimal performance of multilayer blown films. Various tests such as barrier property testing, mechanical property testing, and optical property testing should be conducted to ensure the film meets the required performance specifications. In addition, regular quality control checks should be carried out during the production process to ensure consistent film quality and prevent defects.

From Concept to Final Product : Kung Hsing's Innovative Multilayer Blown Film MachinesAt Kung Hsing, KS, we take pride in being a leading manufacturer in the blown film industry. We offer innovative multilayer blown film machines from concept to final product, backed by our years of experience and advanced technology. Our blown film machines are designed to produce high quality multilayer films with uniform layer thickness, stable film width, lower power consumption, and high productivity. We understand the importance of machine selection in achieving optimal film quality, which is why our machines are customizable to meet specific production requirements and compatible with a wide range of materials used in the film industry. We are committed to providing exceptional after-sales service and technical support to ensure that our customers receive the best possible solutions to their blown film production needs. We strive to deliver efficient and reliable production with excellent film quality, backed by our dedication to quality and customer satisfaction. If you want to learn more about the product, please refer to Blown Film Line. Or contact us today !

|

|||||||||||||||||||||||||||||